Air chain hoist for loads from 250 up to 2000 kg.

These RED ROOSTER Air Chain Hoists are especially developed for heavy industrial use. Robust cast steel body. Valve block is the same for all models meaning: less spare parts required.

Standard features:

- Precise variable speed control (cord- and pendant control).

- Optimum control of the load, very precise positioning.

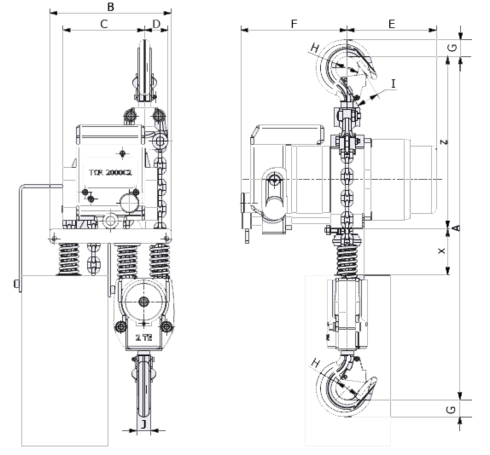

- Compact design.

- Endstop system.

- Load limiter built-in without loss of headroom.

- Cord control or pendant control.

- Low noise level.

- Air pressure 0,4 - 0,63 MPa (4 - 6,3 Bar).

Optional:

- Marine Specification/Corrosion resistant

- Paint systems from C2 - Industrial to C5 - Offshore specification (Red finish as standard. Other RAL colours available on request).

- Choice of pendants.

- Radio control pendant for electro pneumatic controls.

- Control systems.

- Chain collectors (PVC, galvanised or stainless steel).

- Various types of hook or clevis available.

- Air supply systems and valves.

- Air Service unit.

- Piped away exhaust air.

- In house design for "specials".

- Festoon systems.

- Main air shut off valve.

ATEX:

- According to EC Directive 94/9/EC (Ex Classification)

Recommended:

We strongly recommend using an air handling unit, e.g. from SMC (offered separately).